Hardness is a characteristic that applies to a range of materials-metals and nonmetals alike-and is defined as the resistance of the material to deformation, penetration, scratching, or other physical force. Element's experts measure hardness according to the requirements of the material and its applications, with equipment precisely calibrated to the appropriate hardness scales.

The straightforward, timely, and relatively non-destruction nature of hardness testing make it one of the most popular characteristics for engineers interested in materials selection, lot verification testing, the evaluation of material processing, or the comparison of hardness values across multiple material samples. In addition, hardness values can typically be closely correlated with other material properties, such as tensile strength.

Element's expertise in static deformation hardness methods include both macrohardness (applied loads of more than 1 kg) and microhardness (applied loads of less than 1 kg) in accordance with a wide range of industry standards, most of which call for the use of an indenter of known geometry and mass which is forced into the material's surface. The amount of force applied along with the depth of the indentation is recorded and used to calculate the appropriate hardness value for a given point on the sample. Multiple indentations are typically performed to provide a mean hardness value for the entire sample.

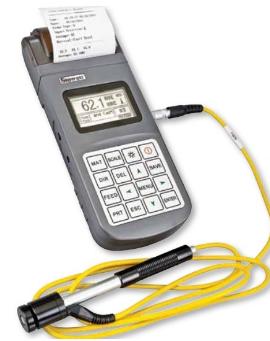

As part of our On-site Metallographic Analysis, we use portable versions of hardness testing to make on-site hardness measurements on large installations or equipment that are either impossible or impractical to ship to a laboratory. We carry out on-site hardness measurements with the following methods:

Element can prepare the surface for each of the above methods and advise you on the most suitable method for your specific project needs. With global access to a team of multidisciplinary engineers and the advanced testing equipment, our hardness measurement services offer the portability, flexibility and high performance for on-site metals verification.